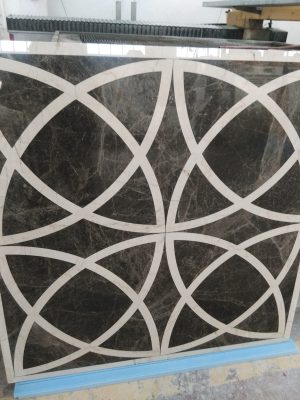

Waterjet Marble

As Hurok Waterjet Project, we meet the needs of many industries in Kütahya with advanced WATERJET (waterjet) technology—now an indispensable production tool for all types of architectural designs, projects, and decorative applications. This technology, which performs drilling and cutting operations with CNC-level precision, plays a vital role in delivering high-quality, custom marble and stone solutions.

WATERJET (Water Jet) is a computer-aided cold cutting technology capable of cutting a wide variety of materials in both 2D and 3D forms. It is perfectly suited for materials such as marble, granite, porcelain, ceramic, linoleum, all types of flooring, and metals. What makes WATERJET exceptional is its ability to cut natural stones without heating, hardening, or causing any deformation. It is the only method capable of cutting porcelain, natural stone, and ceramic with flawless precision. Any complex shape that can be designed on a computer can be achieved using WATERJET technology—making it the most precise, efficient, and cost-effective cutting method available for intricate and custom designs.

The use of WATERJET (water jet) technology in the marble, granite, and ceramic sectors involves cutting slabs or tiles of different colors into any desired shape, and then assembling them side by side or interlocking like a puzzle to form a cohesive design.

This innovative technique allows the production of complex, decorative elements with high precision and visual appeal. Some common applications include:

- Floor medallions in various shapes and patterns

- Wall and floor borders

- Decorative tabletops

- Sink and kitchen countertop inlays

WATERJET technology enables designers and architects to bring their most creative ideas to life with exceptional accuracy and aesthetic quality.

In fact, a custom-designed pattern can be placed on any desired surface exactly as envisioned.

Make room for the signature of Hurok Marble in your life—choose what’s natural.

– Master of Natural Stone